Our Virtual Pipeline delivers LNG to your premises in 10,000-gallon double-walled iso-tank containers that ensure scalable storage systems to cover all your fueling needs.

Our mobile regasification stations convert the LNG back to natural gas for your consumption at rates of 20 thousand cubic feet per hour (MCF/h) and 100 MCF/h.

Fuel all your NGVs. Supplied by our Virtual Pipeline, our Smart Fueling Station delivers a fill rate of 3.2 GGE of CNG per minute. Its versatile configuration can also dispense high-flow and fast-fill CNG, as well as LNG.

24/7 online support and telemetry ensure you a seamless supply of LNG along with operation and maintenance of the fueling and regasification equipment.

Our Virtual Pipeline delivers LNG to your premises in 10,000-gallon double-walled iso-tank containers that ensure scalable storage systems to cover all your fueling needs.

Our mobile regasification stations convert the LNG back to natural gas for your consumption at rates of 20 thousand cubic feet per hour (MCF/h) and 100 MCF/h.

Fuel all your NGVs. Supplied by our Virtual Pipeline, our Smart Fueling Station delivers a fill rate of 3.2 GGE of CNG per minute. Its versatile configuration can also dispense high-flow and fast-fill CNG, as well as LNG.

24/7 online support and telemetry ensure you a seamless supply of LNG along with operation and maintenance of the fueling and regasification equipment.

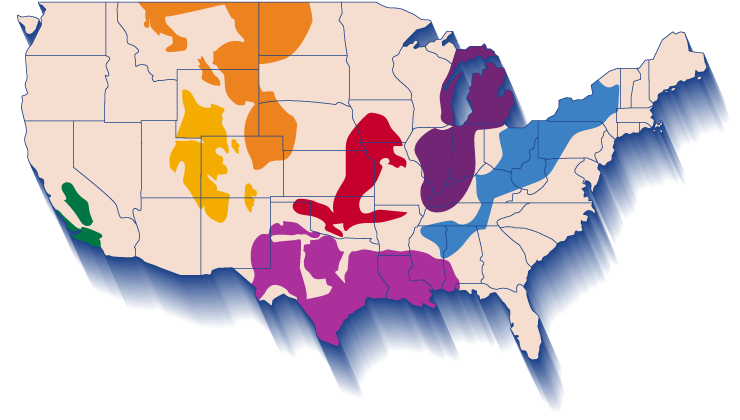

Freedom from using a pipeline means your business is free to fuel up more readily, less expensively, and with a cleaner source of energy than propane or diesel. And no one does it better than Edge Energy.

Our LNG is cheaper than diesel and propane. Three to four trucks of CNG would be necessary to match the same transportation capacity. The savings mean more to invest in your business.

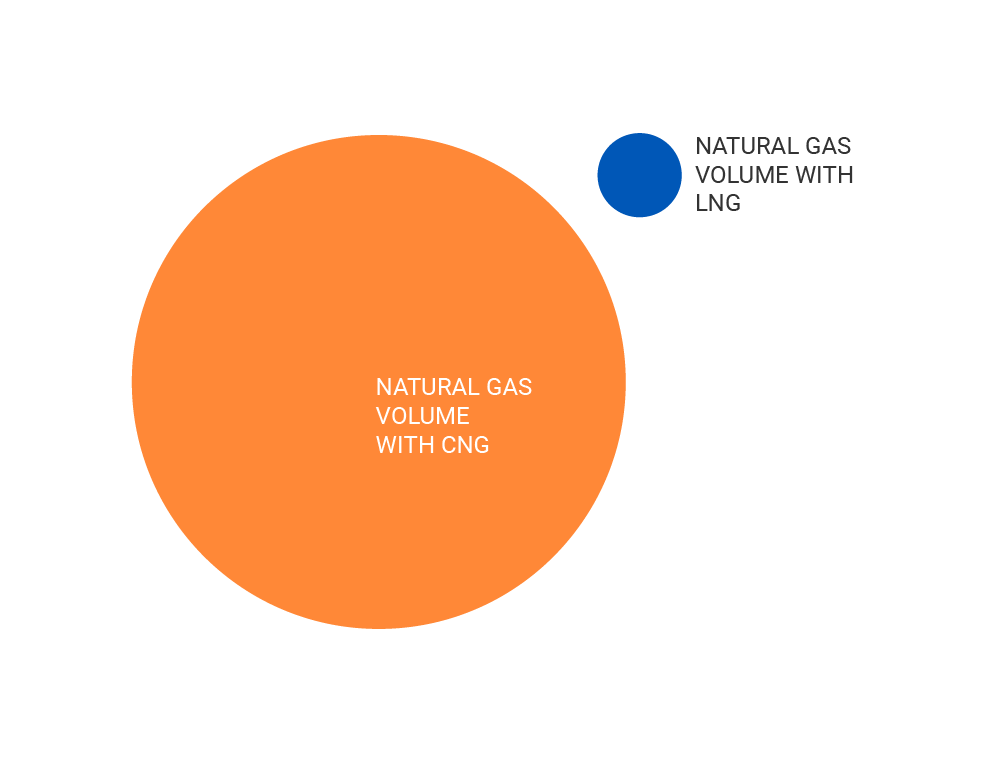

LNG delivers more heating power with less volume than CNG. How much less? LNG reduces the volume of gas by approximately 600 times while CNG reduces it only 60 times. The difference matters.

LNG delivery means fewer trucks on the road and lower emissions from your value-chain. A single iso-tank of our Virtual Pipeline transports approximately 10,000 gallons of LNG. Three to four trucks of CNG would be necessary to match the same transportation capacity.

Our Experts are ready to provide you with additional information, guidance, or price quotes for your energy transition.